A Way to Halt Natural Gas Flaring Arrives on the Back of a Truck

Portable LNG plant chills gas into a liquid, making it easier to ship and store.

A gas flare near Mentone, Texas. Gas often comes up from reservoirs along with oil. Where there isn’t enough of the fuel to exploit commercially, drillers often vent it directly into the air or burn it off at the wellhead. | Photographer: Bronte Wittpenn/Bloomberg

Perched on the back of a semi-trailer is the latest weapon in tackling the problem of wasted natural gas that oil producers often vent into the air or even burn off at the wellhead.

Cryobox takes fuel directly from wells and turns it into liquefied natural gas, which is easy to store and transport.

For small gas fields uneconomical or too distant to connect to a traditional pipeline network, this small-scale LNG plant is a solution to absorb fuel that would otherwise be wasted. That also makes it a way to prevent greenhouse gas emissions that contribute to global warming and solve a growing problem for the industry.

Edge LNG’s Cryobox ready for shipment to a work site. Source: Edge LNG

Wherever oil is produced, gas often follows. If there aren’t enough customers to take it away, the gas is often treated as a waste product and either burned off at the wellhead or allowed to escape into the air—flared or vented in the jargon of the industry.

Making LNG directly at the well can also help recover these supplies known in the trade as “stranded gas” when they aren’t economical to develop or lack pipeline connections. In North America alone, that stranded gas is worth about $600 million.

Cryobox is a product of Edge Gathering Virtual Pipelines 2 LLC. It’s backed by a closely-held Buenos Aries compressor maker Galileo Technologies SA and Blue Water Energy LLP, a private-equity investor managing $2.5 billion.

Movable LNG containers used of for onsite storage of the fuel.

The Cryobox mobile LNG station is one of a growing number of systems that aim to reduce flaring and get gas to where it’s needed. Utilities and industry increasingly see it as insurance from events such as the gas shortage that caused some U.S. automakers to shut during last year’s brutal cold snap.

“The solution is like an Uber for LNG,” said Thomas Sikorski, founding partner at Blue Water Energy, which is based in London. “Trucks with Cryoboxes can run back and forth.”

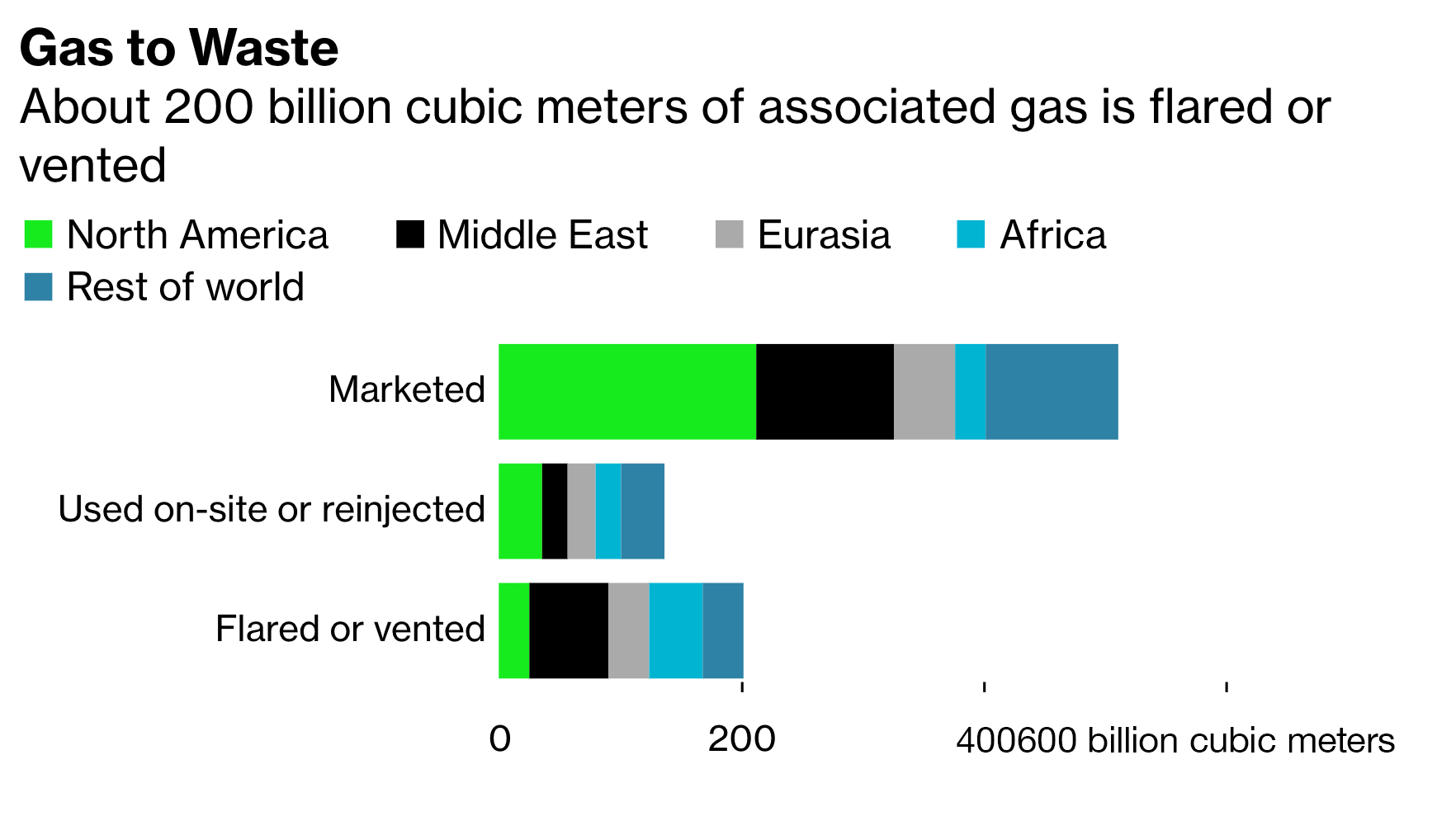

Source: IEA, 2018 data

Soaring gas output from Australia to Russia is inundating the global market, spurring creative solutions to exploit the surplus and help unlock new sources of demand for LNG.

They vary from the basic—compressed natural gas delivered by trucks—to the more complex micro-LNG plants like Cryobox or another solution being built by Siemens AG. One company even installs data centers at shale sites, generating electricity from the surplus gas to mine Bitcoin.

Such smaller-scale applications are growing. Novatek PJSC, Russia’s leading LNG producer, plans this year to start a project to convert mining industry trucks to the super-chilled fuel.

“It’s a huge market opportunity for us,” Mark Gyetvay, chief financial officer of Novatek, said at a conference in Vienna. “These aren’t large-scale projects that are going to move the needle on the demand side, but these are the investments that can help create demand further downstream.”

Edge’s Cryobox can produce as much as 15 metric tons (10,000 gallons) a day of LNG. The rig can be moved between wells and can be up and running within an hour of arriving on site. Peak production is reached in 10 minutes, which is much quicker than the 18 hours it takes for some big conventional liquefaction plants.

LNG transport container fitted to the back of a truck.Source: Edge LNG

The daily output of one unit is a tiny fraction—about one-3,000th—of large-scale plants in Qatar and Russia, but the focus is on the units’ portability. The small scale means the system makes sense for isolated pockets of reserves where it’s too costly to build pipelines and other infrastructure to collect flows. It addresses a growing problem for the industry.

Shale wells produce mostly oil when they’re first fracked, but over time unwanted gas becomes a bigger part of the mix. Flaring rose to a record in Texas last year due to a lack of pipeline capacity to use the fuel.

About 200 billion cubic meters of gas was flared or vented in 2018, more than Japan and China—the world’s biggest LNG buyers—import annually. Globally, 25% of associated gas is wasted, according to the International Energy Agency.

Edge LNG is using its technology in the Marcellus shale in Appalachia, where there are 1,000 stranded wells, to truck LNG northeast. In the Permian Basin in western Texas and New Mexico, the excess gas may be used at drill sites to power machinery instead of costlier diesel, according to Edge LNG.

By the end of the year, the company aims to have a total of 26 Cryoboxes deployed.

“The business can triple in the next two-three years in the U.S. thanks to the huge growth in Permian,” said Edge Chief Executive Officer Mark Casaday. “Not only can the oil companies say they are reducing their cost, but they can say they are cutting their costs by reducing flaring.”

Source: Bloomberg

News

“Record-Breaking Station”: A decade of uninterrupted NGV supply in Spain

With NGV refueling technology developed by Galileo Technologies, Empresa Municipal de Transporte de Madrid continues to reduce its carbon footprint with 400 vehicles powered by clean energy.

Buquebus strengthens its alliance with Galileo Technologies by expanding its LNG manufacturing plant in Argentina

Thanks to Cryobox® technology, developed by Galileo for the liquefaction of natural gas, Buquebus will have a total of nine pieces of equipment in its manufacturing plant, which will result in an increase in production and efficiency in the generation of LNG in Buenos Aires.

India produces LNG for the first time with Galileo Technologies equipment

Thanks to the Cryobox technology, developed by Galileo for the liquefaction for Gail Limited India’s leading natural gas company, will be in charge of supplying LNG to both industries and public transport.

Karpowership and Galileo: A Game-Changing Partnership in the Energy Sector and FLNG Solutions

New memorandum of understanding to form a strategic partnership in a range of technical and commercial areas.